Precision. Productivity. Sustainability.

Manufacturing

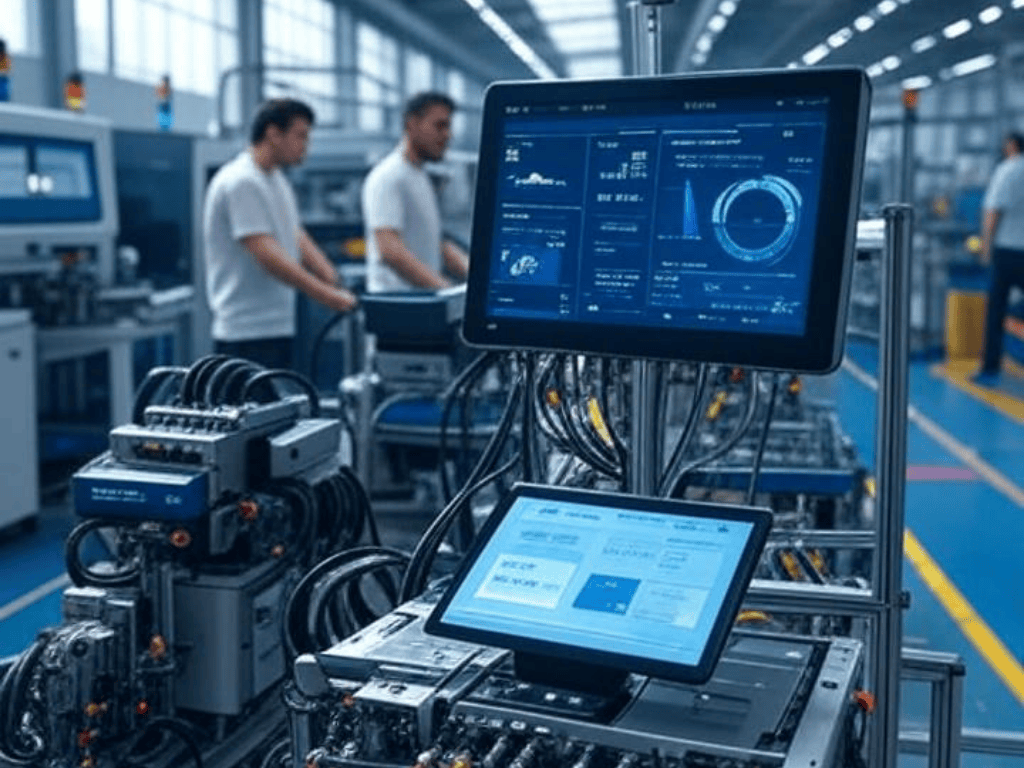

The manufacturing industry is evolving rapidly, driven by IoT (Internet of Things) and Industry 5.0. These technologies combine automation, connectivity, and human creativity to deliver smarter, more sustainable, and highly efficient production systems. Here’s how they can revolutionize your operations.

SMART CONNECTIVTY/REAL-TIME MONITORING

Stay Connected, Stay Ahead

IoT enables seamless communication between devices, ensuring real-time visibility across your production line.

Improved Operational Visibility

Track machine performance and production metrics instantly.

Predictive Maintenance

Leverage real-time data to anticipate equipment failures and minimise downtime, ensuring seamless production processes.

Enhanced Decision-Making

Use real-time, accurate data for faster, smarter decisions.

Quality Assurance Automation

Implement IoT-driven quality checks to maintain high standards and reduce defects in your production line.

Smart Resource Allocation

Reduce costs and waste through automated analysis of production data and efficient allocation of raw materials and resources.

Remote Monitoring and Control

Access and manage your manufacturing operations from anywhere with our secure, cloud-based IoT monitoring platform.

SUSTAINABLE MANUFACTURING

Green Innovation for a Better Future

IoT and Industry 5.0 help manufacturers reduce waste, optimise resource usage and increase efficiency and productivity – ALL sustainably.

Energy Efficiency

Optimise energy consumption across your facilities with our advanced IoT based energy management solutions, reducing costs and environmental impact.

Reduced Waste

Implement automated Implement smart resource monitoring, management and allocation.

Compliance and Reporting

Reduce costs and improve efficiency by automating the monitoring and management of environmental compliance.

Reduce your Carbon Footprint

Minimise greenhouse gas emissions through automated energy monitoring and management.

Turn Waste into value

IoT-enabled tracking systems monitor waste streams and enable automated recycling processes.

Emission Monitoring and Control

IoT sensors track emissions from machines and processes, providing real-time alerts and data driven sustainability reports, ensuring compliance with environmental regulations.

Enhance Brand Reputation

IoT and Industry 5.0 facilitate a demonstrated commitment to sustainability

INTELLIGENT ENERGY MANAGEMENT

Optimize Energy Usage Across Your Facility

IoT sensors and smart grids allow manufacturers to monitor and control energy consumption in real time.

Lower Energy Costs

Reduce unnecessary power usage and peak demand charges.

Dynamic Load Balancing

Automatically monitor and adjust energy distribution based on production needs.

Real-Time Energy Monitoring

Track consumption at every stage of production for immediate optimisation.

Integration with Renewable Sources

Seamlessly incorporate solar, wind, or other green energy into operations.

Predictive Energy Forecasting

Use AI to anticipate future energy needs and prevent shortages.

Automated Shutdown of Idle Equipment

Reduce waste by automatically powering down unused machines.

Energy Storage Optimization

Manage battery systems for robust backup and peak shaving.

ADVANCED DATA ANALYTICS & AI

Turning Data into Actionable Insights

Leverage big data and AI to automatically optimise processes and predict trends.

Process Optimisation

SMART Sensors and monitoring Identify bottlenecks and automatically streamline workflows.

Quality Control

SMART monitoring automatically detects defects early and ensures standards are maintained.

Predictive Analytics

AI-driven insights for production forecasting, fault prevention, and resource optimisation.

Alert & Notification System

Receive immediate alerts for equipment failures, intrusions, or environmental risks.

Historical Data & Reports

Access data trends and generate reports for audits, compliance, and planning.

Remote Access

Manage all farm systems remotely via mobile or web dashboards anytime, anywhere.

Device & Asset Health Monitoring

Track performance and uptime of any device or machine, automate adjustments and prevent failures.

Market Responsiveness

.Integrate market data to automatically adapt production to meet changing demands

Ready to Transform Your Manufacturing Process?

Contact us today to learn how IoT and Industry 5.0 can help you achieve smarter, sustainable, and future-ready operations.